Load and Resistance Factor Design (LRFD): Structural Safety and Efficiency in Modern Engineering

Introduction: Why Structural Design Methods Matter

Structural design is not just a calculation exercise—it shapes how buildings function, how materials are used, and how efficiently structures withstand environmental forces. The methodology used in structural design defines safety margins, affects material efficiency, and influences architectural freedom. Among the leading methodologies in modern structural engineering are Allowable Stress Design (ASD) and Load and Resistance Factor Design (LRFD).

What Is LRFD?

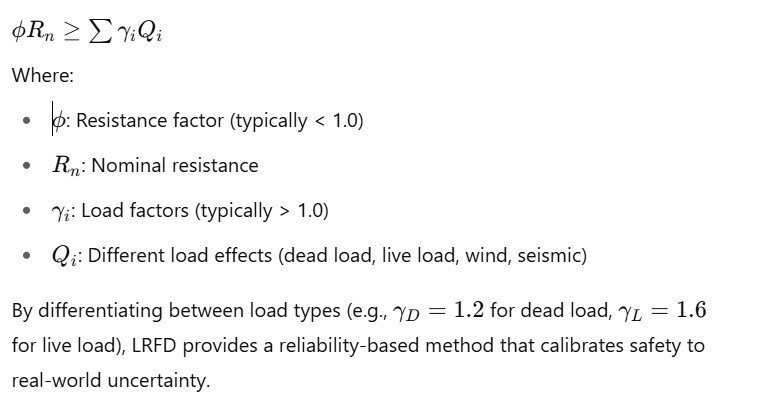

Load and Resistance Factor Design (LRFD) is a modern structural design approach that applies different factors to loads and material resistances based on probabilistic models. Unlike ASD, which uses a single global safety factor, LRFD considers varying uncertainties in load types and material properties by assigning specific load and resistance factors. This results in designs that are not only safe but also more efficient and tailored to real-world risks.

How LRFD Works: Principles and Formulas

At its core, LRFD compares the factored resistance of a structure with the factored loads it must support:

Comparison with Allowable Stress Design (ASD)

| Aspect | ASD | LRFD |

|---|---|---|

| Safety Approach | Single global safety factor | Separate load and resistance factors |

| Load Differentiation | Uniform treatment for all loads | Varies load factors based on risk and uncertainty |

| Material Usage | Often conservative, heavier structures | More optimized, lighter structures |

| Computational Complexity | Simpler calculations | Requires advanced tools and models |

| Common Applications | Wood, masonry, simple structures | Steel, concrete, bridges, high-rises |

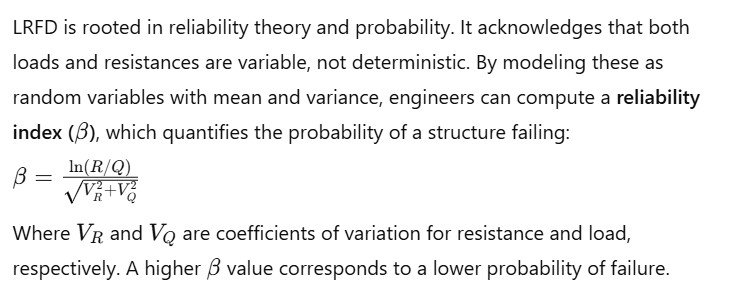

Probabilistic Foundations of LRFD

Advantages of LRFD in Modern Projects

From your professional experience, LRFD offers multiple benefits:

Architectural Efficiency: Slimmer structural members allow more open, flexible interior spaces.

Cost-Effectiveness: Optimized material use reduces costs without compromising safety.

Adaptability: Ideal for complex scenarios like seismic design, long-span roofs, and tall buildings.

Sustainability: Less material usage means reduced embodied carbon, supporting green building goals.

Applications Across Industries

LRFD is now the standard in many structural codes worldwide. In the U.S., agencies like AISC, ACI, and AASHTO have adopted LRFD for steel, concrete, and bridge design. Internationally, Eurocodes and Australian Standards align with LRFD principles, making it the de facto method for global engineering projects.

From Theory to Practice: Bridging the Gap

Despite its advantages, LRFD’s complexity can be a barrier for early-stage designers and architects. This is where simplified structural analysis methods come into play. By using equilibrium, graphical tools, and empirical rules, architects and engineers can estimate load paths and structural behavior quickly—before detailed LRFD models are developed. These simplified tools bridge conceptual design and technical execution.

Why LRFD Represents the Future

LRFD isn’t just a safer alternative to ASD—it’s a smarter one. Its probabilistic framework, tailored safety margins, and alignment with modern computational tools make it the preferred choice for 21st-century structural engineering. As you’ve seen firsthand, it supports better architecture, smarter material use, and stronger, more adaptable structures. In a world facing escalating environmental demands and complex building requirements, LRFD delivers safety, sustainability, and structural excellence.