Rethinking Structural Efficiency in the Age of Sustainability

Sustainability in structural design is no longer optional—it is essential. As climate urgency intensifies and construction regulations evolve, the structural engineering community is moving beyond the legacy mindset of strength-at-any-cost. Today, sustainability and structural efficiency are intertwined concepts: the most effective structures are those that maximize performance while minimizing environmental and material impact.

Modern structural efficiency is not merely about strength—it’s about optimization. A well-designed building leverages material intelligence, passive strategies, and minimal intervention to achieve lasting performance. This means lighter structures requiring less foundation depth, materials designed to endure decades with minimal maintenance, and hybrid systems that balance load, flexibility, and long-term adaptability.

Engineered Timber: Redefining Renewable Strength

Engineered wood products like cross-laminated timber (CLT) and glue-laminated timber (glulam) offer high strength-to-weight ratios and consistent performance. CLT, in particular, is manufactured by layering timber panels crosswise and bonding them to form large-scale structural elements. This allows it to replace steel or concrete in mid-rise and even tall building projects, all while reducing embodied carbon and enabling carbon sequestration.

Prefabrication and modular assembly of CLT further enhance its appeal, reducing on-site waste and accelerating construction schedules. With advancements in fire resistance and moisture protection, engineered timber is becoming a mainstream structural solution—not a compromise.

High-Performance Concrete: Carbon Reduction Without Compromise

Concrete remains foundational in structural engineering, but innovations are rapidly transforming its environmental profile:

Geopolymer concrete, which uses industrial waste products like fly ash, reduces CO₂ emissions by up to 80% compared to traditional Portland cement.

Recycled aggregate concrete diverts waste from landfills and reduces demand for virgin raw materials.

Self-healing concrete, activated by embedded bacteria or capsules, significantly extends structure lifespan and minimizes maintenance.

Ultra-high-performance concrete (UHPC), with its exceptional compressive strength and durability, allows thinner sections and longer spans, making it ideal for bridges and high-load applications where both efficiency and longevity are paramount.

Recycled and High-Strength Steel: Efficiency in the Circular Economy

Nearly 90% of structural steel is recycled, making it a natural fit for sustainable construction. High-strength steel variants enable lighter, more efficient design while maintaining critical load-bearing capacity. Modern fabrication methods, such as electric arc furnaces powered by renewable energy, are further reducing steel’s carbon footprint.

Steel’s modularity allows disassembly and reuse, aligning with circular design principles and making it a key player in both large-scale infrastructure and modular building systems.

Bamboo & Hempcrete: Bio-Based Efficiency

Bamboo offers a compelling mix of strength, renewability, and flexibility. With tensile strength rivaling steel and compressive strength comparable to concrete, it is a prime candidate for lightweight structures, especially in seismic regions. Engineered bamboo products enhance consistency and scalability.

Hempcrete—a blend of hemp fibers and lime—provides structural stability in non-load-bearing walls while delivering exceptional insulation and carbon sequestration benefits. Its low weight reduces foundation requirements, further improving structural efficiency.

Adaptive & Smart Materials: The Future is Now

Next-generation materials are blurring the lines between structure and function:

Phase-change materials (PCMs) regulate indoor temperatures by storing and releasing heat.

Shape-memory alloys adapt to environmental stressors, improving resilience.

Bio-responsive composites and dynamic glazing enhance adaptability without energy input.

These smart materials are making buildings not just sustainable but responsive, helping them function more like ecosystems than machines.

Strategic Design for Maximum Efficiency

Even the greenest material can become inefficient if poorly applied. Structural design strategies must complement sustainable materials to unlock their full potential.

Structural Form Optimization

Architects and engineers can reduce material usage through geometry:

Shells and domes distribute forces efficiently, reducing material volume.

Vaulted and ribbed slabs offer high load capacity with minimal thickness.

Tensile structures achieve stability with tension rather than mass.

Working with, not against, natural forces enables leaner, smarter structures.

Prefabrication & Modular Systems

Prefabricated elements made from engineered timber, high-performance concrete, or steel are produced under controlled conditions, ensuring precision and reducing waste. Modular construction also enables buildings to be expanded, reconfigured, or disassembled with ease—extending material life and minimizing demolition waste.

Lightweight Construction Principles

Reducing dead load minimizes foundation requirements and increases seismic performance:

Engineered wood and bamboo reduce weight without compromising strength.

Aerated and geopolymer concretes cut mass while improving insulation.

Hybrid systems balance strength, weight, and environmental impact.

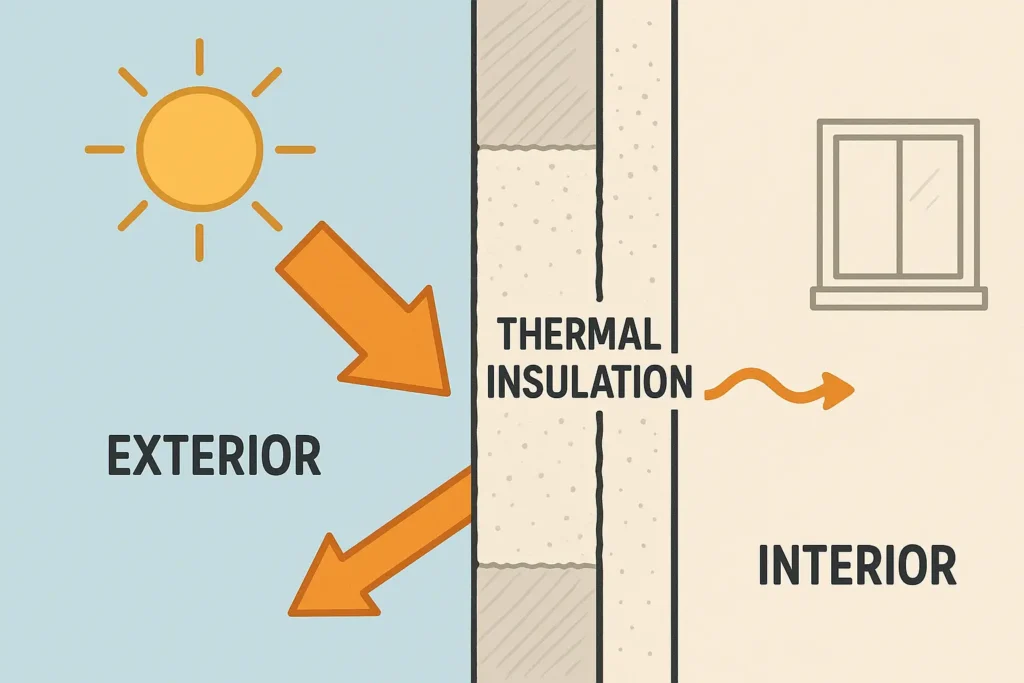

Passive Design Integration

Materials and form should align with passive energy strategies:

High thermal mass concrete and natural ventilation reduce HVAC loads.

Insulating materials like hempcrete and engineered wood improve envelope efficiency.

Smart orientation and green facades lower energy demand while improving comfort.

Designing for Adaptability

Buildings must evolve with use:

Reconfigurable CLT and steel systems allow interior changes without structural overhaul.

Multi-use structural components, like solar-integrated façades, serve multiple functions.

Design for disassembly ensures components can be reused, not discarded.

Adaptability increases longevity and reduces the environmental cost of change.

Navigating the Challenges of Sustainable Materials

Adopting green materials comes with real-world hurdles:

Structural performance limits in some bio-based options.

Moisture and fire resistance concerns in timber and bamboo.

Higher upfront costs due to limited market penetration.

Scaling issues with material sourcing and manufacturing.

Code compliance and industry inertia resisting innovation.

Yet these challenges are already being addressed through ongoing research, public policy support, and increased demand. Innovations in material science and circular design are making green materials more accessible, affordable, and reliable.

Building Smarter, Stronger, and Greener

Sustainability and structural design are no longer separate disciplines—they are interdependent forces shaping the future of construction. By integrating green materials, optimized geometry, and adaptive systems, we can design structures that are lighter, stronger, more resilient, and more responsible.

Whether through cross-laminated timber, recycled steel, self-healing concrete, or bamboo-reinforced hybrids, the tools for sustainable structural design are already here. The task now is to use them intelligently, balancing innovation with integrity.

Sustainable structures do more than meet code—they inspire change, proving that efficiency, resilience, and environmental stewardship can be achieved together. The path forward is not just greener—it’s smarter, stronger, and built to last.